New Technology of Plastic Mould Design and Manufacturing

Release time:

2021-10-16 11:02

Source:

Plastic molds occupy a very important position in plastic processing. The level of mold design and manufacturing also reflects the industrial level of a country. In recent years, the output and level of plastic molding molds have developed very rapidly, with high efficiency, automation, large-scale, precision , The proportion of long-life molds is increasing. The following summarizes the development status of molds from the aspects of mold design, processing methods, processing equipment, and surface treatment.

Plastic molding method and mold design

Gas-assisted molding, gas-assisted molding is not a new technology, but it has developed rapidly in recent years and some new methods have emerged. Liquefied gas assisted injection is to inject a preheated special gasifiable liquid from injection into the plastic melt. The liquid is heated and gasified in the mold cavity and expands, making it hollow and pushing the melt to the mold cavity. surface, this method can be used for any thermoplastic. Vibration gas-assisted injection is to apply vibration energy to the plastic melt by oscillating the compressed gas of the product, so as to achieve the purpose of controlling the microstructure of the product and improving the performance of the product. Some manufacturers convert the gas used in the gas-assisted molding to form thinner products. It is also possible to produce large hollow products with higher quality and lower cost, but the key point is the problem of water leakage,

Push-pull molding mold, two or more channels are opened around the mold cavity, and are connected with two or more injection devices or pistons that can move back and forth. After the injection is completed, the screw or piston of the injection device is This technology is called dynamic pressure holding technology by moving the melt in the cavity back and forth, and its purpose is to avoid the problem of large shrinkage of thick products formed by traditional molding methods. It is a product with a long process ratio, and a multi-point gate mold is often used, but multi-point pouring will cause fusion seams, which will affect the visual effect of some transparent products. Single-point pouring is not easy to fill the mold cavity, so it can be It is formed by high-pressure molding technology. For example, the cockpit of the F16 fighter jet is produced by this technology. At present, this technology has been used to produce PC car windshields. The injection pressure of high-pressure molding is generally more than 200MPA, so the mold material must Select high-strength rigidity with high Young's modulus. The key to high-pressure molding is the control of mold temperature. In addition, it is necessary to pay attention to the smooth exhaust of the mold cavity. Otherwise, the high-speed injection will cause poor exhaust and scorch the plastic.

Hot runner mold: Hot runner technology is increasingly used in multi-cavity molds, and its dynamic advancement technology is a bright spot in mold technology. That is, the flow of plastic is adjusted through a needle valve, and parameters such as injection time and injection pressure can be set separately for each gate, so as to obtain balance and injection and the best quality assurance. The needle valve can be driven by hydraulic pressure. The position of the needle valve determines the flow and pressure of the injection. There is a pressure sensor in the flow channel, which can continuously record the pressure in the channel, and then can control the position of the needle valve and adjust the melt pressure.

Mold for molten core injection molding: This method is to put the fusible core made of low melting point alloy into the mold as an insert for injection molding. The article containing the fusible core is then heated to remove the fusible core. This molding method is used for products with complex hollow shapes, such as hollow plastic parts with complex shapes such as fuel pipes or exhaust pipes of automobiles. Products formed with this type of mold include: tennis racket handle, automobile water pump, centrifugal hot water pump and spacecraft oil pump, etc.

Injection/compression molding molds: Injection/compression molding can produce low stress. For products with good optical properties, the process is: mold clamping (but the movable and fixed molds are not completely closed, leaving a gap for later compression), injecting melt, and secondary mold closing (that is, compression causes the melt to be compressed in the mold. Compaction), cooling, mold opening, demoulding. In the mold design, it should be noted that since the mold is not completely closed when the mold is closed, in order to prevent overflow during injection, a structure to prevent overflow should be designed in the mold.

Laminated mold: Arrange multiple cavities overlapping on the clamping side instead of arranging multiple cavities on the same plane, which can give full play to the plasticizing ability of the injection machine. This mold is generally used in hot runner molds, which can be extremely greatly improve efficiency,

Injection mold for layered products: The injection molding of layered products has the characteristics of co-extrusion molding and injection molding. It can realize multi-layer combination of different materials of any thickness on the product. The thickness of each layer can be as small as 0.1~10mm. up to thousands. This mold is actually a combination of an injection mold and a multi-stage co-extrusion mold.

Die slip forming (DSI): This method can form hollow products and composite products of various materials. The process is: closing the mold (for hollow products, the two halves of the cavity are in different positions at this time), Inject separately, the mold moves to the two halves of the cavity, and the resin that combines the two halves is injected in the middle. Compared with blow-molded products, the products formed by this method have better surface accuracy, high dimensional accuracy, and uniform wall thickness. Design freedom and other advantages.

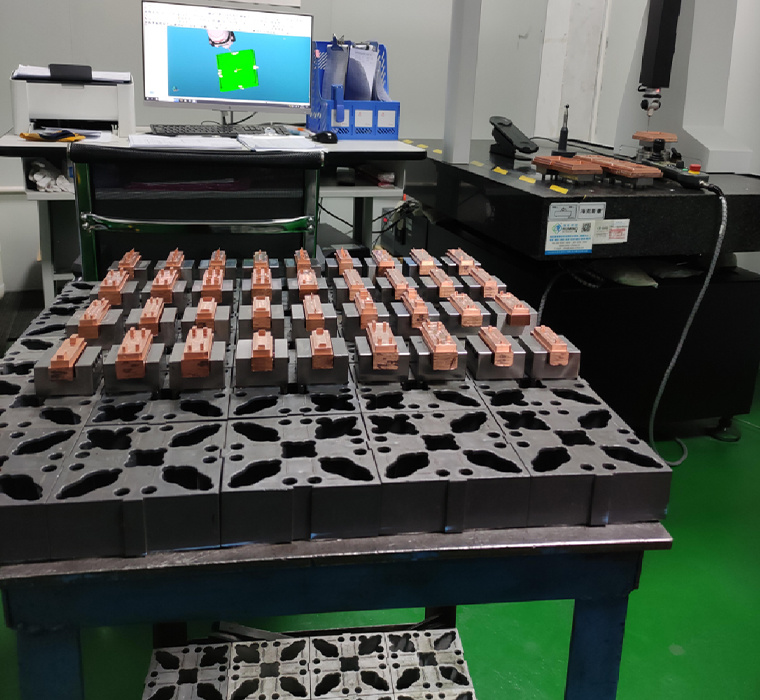

Aluminum mold: A prominent point in plastic manufacturing technology is the application of aluminum-gold materials. The service life of the aluminum alloy plastic mold developed by Corus can reach more than 300,000. More than 500,000 times

Related news