What factors affect the polishing of plastic molds

Release time:

2022-01-25 09:51

Source:

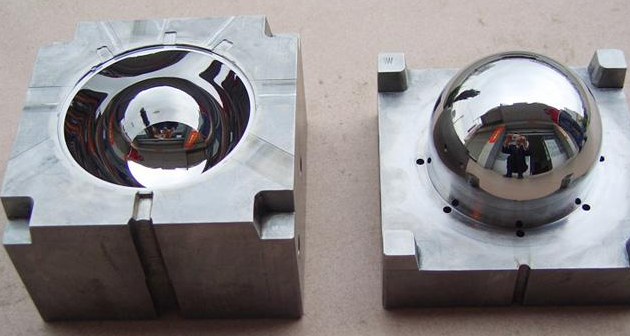

Plastic products are already very common products in production and life, including many industrial products that also use plastic raw materials. Some products have very high requirements on appearance, which requires mirror polishing of product molds in the process of manufacturing and processing. Plastic mold polishing can not only meet the requirements of product appearance gloss, but also improve product corrosion resistance. resistance and wear resistance. Therefore, mold polishing is of substantial benefit to the product. So how to polish the mold well, and what are the specific influencing factors, today we will focus on this content.

Factors Affecting Mold Polishing

1. Heat treatment process

If the heat treatment is improper, the surface hardness of the steel is uneven or the characteristics are different, which will cause difficulties in polishing.

2. The quality of steel

High-quality steel is a prerequisite for obtaining good polishing quality. Various inclusions and pores in the steel will affect the polishing effect. To achieve a good polishing effect, the workpiece must be marked with the surface roughness of polishing at the beginning of machining. When a workpiece is determined to need mirror polishing, it must choose steel with good polishing performance and undergo heat treatment, otherwise it will not meet expectations. Effect.

3. Polishing technology

Yishun mold polishing then analyzes for everyone. Since polishing is mainly done manually, human skills are still the main reason for affecting the quality of polishing. It is generally believed that polishing technology affects surface roughness. In fact, good polishing technology needs to cooperate with high-quality steel and correct heat treatment process to obtain satisfactory polishing effect; on the contrary, if polishing technology is not good, even if the steel is good, it will not be able to achieve a mirror effect. .

4. Surface condition of workpiece

During the machining process of the material, the surface layer will be damaged due to heat, internal stress or other factors, and improper cutting parameters will affect the polishing effect. EDM surfaces are more difficult to grind than machined or heat treated surfaces, so EDM finishing should be used before the end of the EDM process, otherwise a hardened thin layer will form on the surface. If the EDM finishing specification is not properly selected, the depth of the heat-affected layer can be up to 0.4mm. The hardened thin layer is harder than the matrix and must be removed. Therefore, it is best to add a rough grinding process to provide a good foundation for polishing.

Related news